Indicators on Sheroz Earthworks You Should Know

Indicators on Sheroz Earthworks You Should Know

Blog Article

Some Known Facts About Sheroz Earthworks.

Table of ContentsThe Main Principles Of Sheroz Earthworks The Basic Principles Of Sheroz Earthworks Getting The Sheroz Earthworks To WorkWhat Does Sheroz Earthworks Do?The Only Guide to Sheroz Earthworks

For any earthwork professional, it is vital to do work with top quality, accuracy, and on timetable. Utilizing device control in job makers enables optimizing the different phases in the earthwork process, from planning to the maintenance stage - trimble gps. The maker control system helps the device operator in obtaining the target airplane rapidly and quickly

The device control system guides the driver with centimeter accuracy. Remote support saves time and cash, as it decreases downtime in jobsites.

The smart Trick of Sheroz Earthworks That Nobody is Talking About

Our system's elements are very carefully developed to stand up to the rough problems of building and construction sites. Comparison of the exact same project performed utilizing maker control versus the typical approach discloses that, on standard, the standard approach calls for 50% more time to complete the exact same task as the technology-assisted approach.

Sounds good, best? Enter the Xsite equipment control system; it's right here to give you with a substantial advantage when collaborating with earthmoving machinery. Discover exactly how Xsite Machine Control can improve your productivity and make certain work safety and security! We recognize that discovering a brand-new innovation may feel like a drag, but don't worry! Our pleasant and expert regional support solutions have got you covered, guaranteeing that you can maintain working smarter without disturbances while at work! Via remote support, your local Xsite supplier can supply guidance or troubleshooting without having to visit the website! What kind of excavators does machine control fit? Xsite Device Control systems can be mounted to any type of excavator from mini excavators to large mining excavators.

Just how does equipment control work? In 2D systems, the equipment is geared up with calibrated inclination sensing units. These sensors are installed on the pre-determined components of the maker in excavators the sensing unit are usually placed to the frame, boom (or booms), digger arm and to the quick coupler - topcon. By utilizing the data gotten from these sensing units the system can calculate the precise setting of the excavators pail pointer in relevance to a referral point.

The system is extremely easy to find out the fundamentals can be shown in under one hour of training. Exactly how does the remote support work? A cordless internet link makes it possible to develop a remote connection in between the maker control system and the service.

Sheroz Earthworks Things To Know Before You Get This

What type of information formats Xsite systems support? Xsite Device Control systems sustain open typical data formats, making it possible for seamless info circulation from one system to one more. Sustained file styles: 2D-Maps: navigate to this site DXF Factor data: DXF, XML, GT, CSV, KOF, PXY Geometry lines: VGP, SBG, XML, Anpakke Surface Designs: DXF, XML What components are mounted on my device? Depending upon your selection of system (with or without placing, i.e - fj dynamics autosteer review., 2D or 3D), your equipment is geared up with inclination sensing units, a controller device, and a display/operating panel.

Several hardware and software options exist to assist establish a machine's present position on the earth and contrast it with a desired design surfaceand building operators can do more to leverage the benefits. Equipment control is the use of numerous placing sensing units and a display screen to offer the driver with a reference between the position of the container or blade and the target quality.

Relying on the configuration, maker control systems can offer the operator with a basic aesthetic guide to bucket or blade setting, or can immediately move the blade to grade by speaking to the machine's hydraulics - https://www.kickstarter.com/profile/sherozau/about. There are device control systems offered for practically any kind of maker: graders, dozers, excavators, dirt and asphalt compactors, scrapes, leaners, grating machines, and pavers

How Sheroz Earthworks can Save You Time, Stress, and Money.

Device control can also help raise efficiency and minimize overall costs. Construction tools without device control will certainly come to be a point of the past and the advantages got from it will be many.

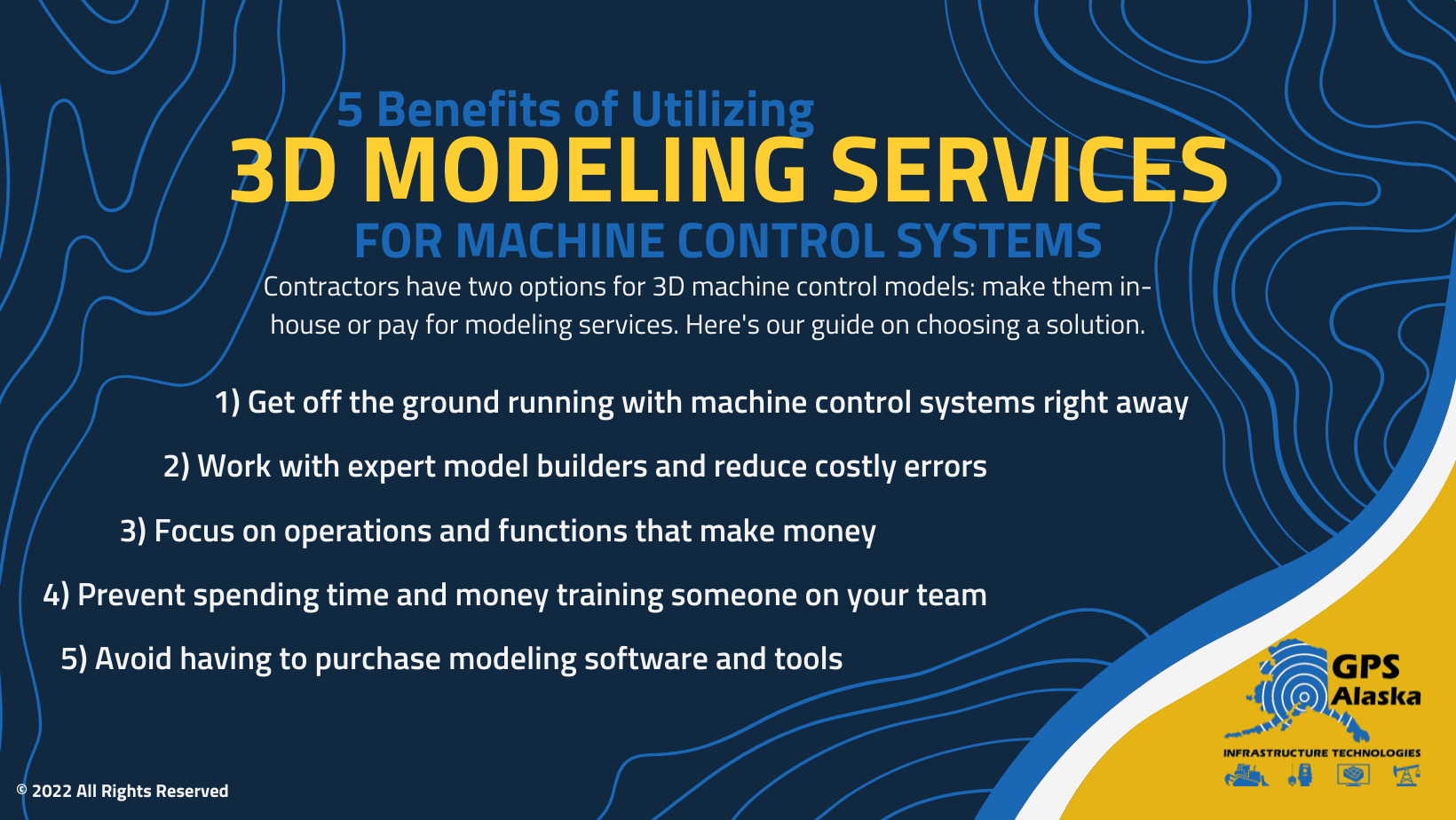

Trimble device control systems supply a myriad of advantages to anyone that uses earthwork machinery and, at EarthCalc, we can offer you with 3D apply for your device control-enable tools. Not exactly sure if equipment control deserves the cost? Think about the adhering to factors why you require to consider this alternative.

Using GPS lined up with your 3D layout files, these systems practically ensure that you will certainly remove or place the right quantity of product at the construction site. On a lot of building and construction sites, remodel is a common and discouraging reality, however with Trimble machine control, you can eliminate the demand for rework.

Sheroz Earthworks for Dummies

Frequently, with Trimble maker control, you can get rid of excess tools at a specific job website. For example, a task that may have called for the usage of three or four pieces of excavating devices currently could need just 2 items of devices to accomplish the same task in much less time. This allows you to relocate your devices to another job website and take care of several tasks at one time.

Report this page